Emerging tech like AI, CAD, and robotics are revolutionizing repairs across sectors, addressing critical repair quality concerns. AI algorithms analyze historical data for insights, while robotic systems execute intricate work with speed and consistency. In automotive, these technologies enhance body panel alignment, tire services, and overall repair quality, allowing human technicians to focus on complex tasks. Investing in these innovative tools drives excellence in repair quality and optimizes workflow processes.

In an era where technological advancements are reshaping industries, addressing repair quality concerns is more critical than ever. This article explores cutting-edge trends poised to revolutionize the landscape of repair services. From the integration of AI and robotics for enhanced precision to sustainable practices minimizing environmental impact, these innovations aim to transform how we approach repairs. Additionally, we delve into data analytics’ predictive capabilities, showcasing their potential in preventing costly downtime and prolonging equipment lifespan. By embracing these future trends, industries can elevate repair quality standards and drive operational excellence.

- Emerging Technologies for Enhanced Repair Precision

- – Exploring the role of AI and robotics in improving repair accuracy and efficiency.

- – Case studies demonstrating successful implementation of these technologies.

Emerging Technologies for Enhanced Repair Precision

The future of repairs looks set to be reshaped by emerging technologies that promise enhanced precision and improved accuracy. Innovations such as artificial intelligence (AI), computer-aided design (CAD), and robotic systems are being integrated into repair processes, enabling technicians to achieve a new level of detail and consistency. AI algorithms can analyze vast amounts of data from previous repairs, providing insights that lead to more effective solutions for specific issues. This not only boosts the speed and efficiency of repairs but also ensures consistent high-quality outcomes.

In the realm of automotive repair, these technologies are being utilized to fine-tune everything from body panel alignment to intricate tire services. Collision repair services, for instance, can benefit significantly from AI-driven systems that detect and rectify minor imperfections with remarkable precision. This advanced approach promises not only to restore vehicles to their pre-accident condition but also to set new standards in repair quality concerns across various sectors, including automotive, manufacturing, and even aerospace.

– Exploring the role of AI and robotics in improving repair accuracy and efficiency.

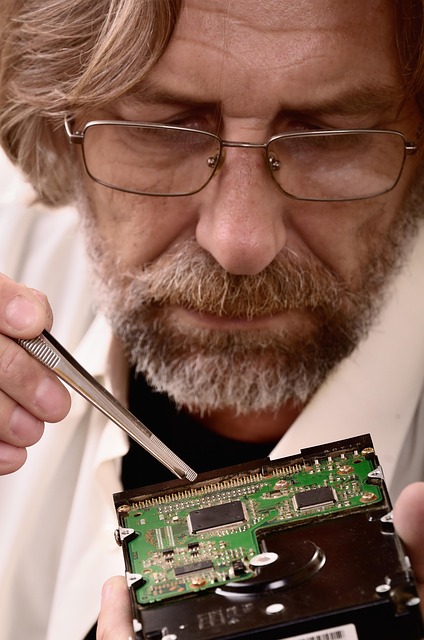

The integration of Artificial Intelligence (AI) and robotics is poised to revolutionize the landscape of vehicle body repair, specifically addressing pressing repair quality concerns. AI algorithms can analyze complex data sets from previous repairs, identifying patterns and trends that human eyes might miss. This enables more precise predictions about material properties and structural integrity during frame straightening processes, resulting in improved repair accuracy.

Robotic systems equipped with advanced sensors can perform tasks with unprecedented consistency and speed. They are ideal for handling intricate auto body work, ensuring minimal errors and saving time. By automating repetitive tasks, these technologies allow human technicians to focus on more complex aspects of vehicle body repair, enhancing overall efficiency.

– Case studies demonstrating successful implementation of these technologies.

In recent years, the automotive industry has witnessed a significant shift towards embracing innovative technologies to address pressing repair quality concerns within collision centers and car scratch repair shops. These advanced solutions are revolutionizing the way damages are assessed, repaired, and prevented. For instance, many successful case studies highlight the implementation of computer-aided design (CAD) software in collision repair shops. This technology enables precise measurements and visualization of vehicle panels, ensuring that every repair is tailored to the exact specifications of the make and model. As a result, these digital tools have led to reduced repair times and improved overall quality, setting new benchmarks for the industry.

Additionally, the adoption of robotic systems in collision centers has proven to be a game-changer. These robots can handle repetitive tasks with unparalleled accuracy, allowing human technicians to focus on more complex repairs. A notable example involves a leading car scratch repair service that integrated robotic welding technology. This innovation not only enhanced the speed and consistency of panel replacements but also reduced the risk of human error, resulting in higher customer satisfaction rates and a more efficient operation. Such successful implementations demonstrate that investing in cutting-edge technologies can drive excellence in repair quality while optimizing workflow processes within collision centers and car scratch repair shops.

The future of repairs looks promising with the integration of emerging technologies, particularly AI and robotics, which are set to transform the industry. These innovations aim to address longstanding repair quality concerns by enhancing precision, efficiency, and overall productivity. As demonstrated through successful case studies, the adoption of these advanced tools promises not only improved outcomes but also cost savings and faster turnaround times. By leveraging AI and robotics, repair professionals can navigate the evolving landscape, ensuring higher-quality repairs and staying ahead in a competitive market.